Three methods of checking the measurement of filling machine by Lugong machinery

2022-03-26

author:

吕工机械

Veiw:

863

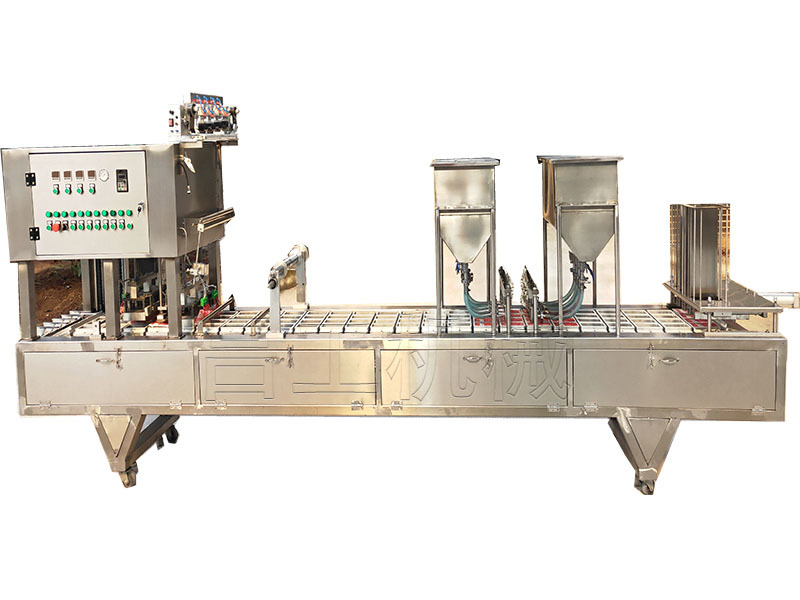

Wuhan Lugong Machinery Co., Ltd. pointed out that the quantitative filling machine is a machine that measures and fills by controlling the liquid volume filled into the packaging container. It has simple structure, reliability and few faults. It adopts cone piston, with good sealing performance, accurate liquid injection and convenient liquid volume adjustment. So

Lvgong machinery inventory filling machine measurement of three methods:

1. Electronic metering method of filling machine

The electronic metering method of the filling machine is a kind of weight measurement. There are two liquid channels with different sizes on the filling valve. When the oil passes through the liquid channel, the load sensor measures the oil weight in real time. When the filled liquid is close to the specified filling amount, the filling valve of the filling machine can be converted into a small flow circuit until the filling reaches the specified amount. The display of the filling machine of this device is cleared before filling, and if there is a measurement deviation in the container weight, it will be reset, which has no impact on the filling volume, so the accuracy of this filling volume is very high. When the filling volume changes, it can be realized instantaneously as long as the given value of the data switch is changed, which is easier to realize the centralized management of production.

2. Filling machine quantitative pump quantitative method

Filling machine quantitative pump quantitative method, which is a quantitative method of filling by pressure method. The reciprocating motion of the piston is controlled by power to suck the edible oil from the storage cylinder into the piston cylinder, and then press it into the filling container. Each filling amount is equal to the volume of materials in the piston cylinder. In addition, a layer of soft film is used to suck the material from the material cylinder into the filling chamber under the action of gas pressure, and then inject it into the container.

3. Quantitative method for controlling liquid level height of filling machine

The filling machine controls the liquid level height quantitative method, which achieves quantitative filling by controlling the liquid level height in the filled container. The volume of edible oil filled by each filling machine is equal to the volume of the inner cavity of the bottle with a certain height, so it is also called "quantitative by bottle". This method has simple structure, no auxiliary equipment and convenient use, but it is not suitable for products requiring high quantitative accuracy, because the volumetric accuracy of bottles directly affects the accuracy of filling volume.

The above is the "three methods of checking the measurement of filling machine by Lvgong machinery" introduced by Xiaobian. I believe you have a certain understanding of the measurement method of filling machine. The accurate quantitative filling of products not only involves the cost, but also affects the reputation of products in the eyes of consumers. Therefore, when purchasing filling machine equipment, please be sure to choose professional and regular filling machine manufacturers.

Keyword:

武汉吕工机械有限公司,灌装机

What are the current problems encountered by the manufacturing industry?

01. High intensity of physical labor and high turnover rate

02. Labor efficiency is low, and the later operation cannot keep up with the front-end production

03. Manual work is difficult to recruit, and the labor cost is high

04. The error rate of operators is high, which is easy to cause huge losses

05. The workshop is messy and there are various potential safety hazards

06. Waste production space and increase unnecessary costs

One stop packaging machinery solution

Seamless connection

One bag count line

1-N docking stations

Artificial intelligence packaging machine

Accurate measurement

Can do

The weight of each package meets the range

The precision of each large package is more than 99.9%

Save labor

A bag counting line for 20 machinesOnly 2-3 people are required to operateSave 80% - 90% labor

High cost performance

More efficient

Lower loss

One year to return

Consult immediately

Recommended news

- Consulting service

Call

WeChat

WeChat

QR code

- TOP